Wool - It's All in the Family!

Posted by Kim Brooks on 1st May 2014

Slotted into the same family, wool, or sheep’s wool and alpaca wool, or alpaca, can often be spoken of in the same sentence. While vastly similar, and vastly different, now is the time to understand these cousins and how they compare.

Wool, regardless of what species is a protein fiber, much like the hair growing on your head. Both hair, and wool of any type is a keratin. Keratin can also be found in skin, fur, claws, nails, hooves, horns, scales, beaks and feathers.

Careful breeding

Sheep’s wool didn’t just happen. Wild sheep grew a fleece that was much more hairy than wooly. Sheep were domesticated between nine and eleven thousand years ago. Around 6000 BC sheep’s hair, after careful and selective breeding, evolved into the bouncy, crimpy fluff we know today as wool.

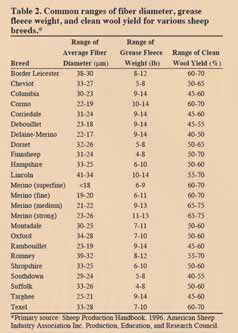

Much like our Suri and Huacaya alpacas, sheep today have two distinct types; hairy and woolly. Sheep however, have evolved into secondary breeds, dependent upon the type of wool they produce. You may be familiar with these shown in Table 2.

These types all have origin identifiers, meaning that Merino, for example, is different in the US than in France. Marino from France differs from Spain or the UK, not to mention Australia or South Africa. This makes sense as husbandry, technology, terrain and temperature all add up and affect the livestock.

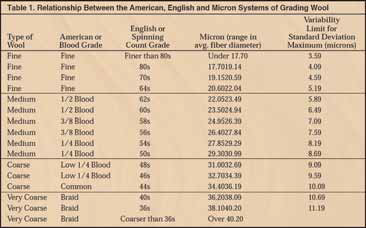

Wool has over the years, been divided by grades, and, oddly enough, by country. These are American or Blood Grade, English or Spinning Count Grade and Micron. The American Blood Grade System was developed in the early 1800s and originally represented the amount of fine-wool Merino genetics present in the sheep. The English or Spinning Count uses a measurement based on the number of “hanks” of yarn, which could be spun from one pound of clean wool on the equipment available at the time the system was developed. These clearly demonstrate the need to type wool, regardless of the century, for fineness and production. Today, while they are all still considered and used to some degree, the micron grade is the most used.

In Table 1 you can see the ingenuity of the time was able to come up with methods, relatively close to those derived from modern Micron testing, which provided the needed information.

Wool Stats 101

Given centuries of study, the volumes of information on wool can boggle the mind. You may want to do some research yourself as the wool industry directly impacts the alpaca wool industry.

Through Google searching one can find enlightening information that is curiously similar to the struggles and successes of our alpaca wool industry.

The world wool production is approximately two million tons per year and of that volume, roughly 1.6 million tons, or80% is used in the production of apparel. Today Australia is the largest producer of wool, growing more than 20%. They are followed closely by China, New Zealand and the UK. Argentina, Morocco, the Sudan, Russia, Syrian Arab Republic, Pakistan, and South Africa contribute only 2 or 3% each to the world’s pool, while the US contributes less than 0.75%

In 2010, the average price paid for sheep’s wool sold in the United States was $1.15 per pound for a total value of $35.3 million. 30.6 million pounds of wool was harvested from 4.22 million head of sheep and lambs in 2010. The average fleece weight was 7.3 pounds (3.32 kg).

The United States was the world’s fifth largest wool-producing nation in the 1940s. At the time, wool was considered to be the primary product of sheep production with lamb and mutton as byproducts. As the fortunes of the US sheep industry declined over the years, along with the ability to process sheep’s wool domestically, so did the relative return to wool production. As a consequence sheep producers and researchers have turned their attention to improving lamb and mutton production. Sheep producers today can get more money for their wool if they direct market it to hand spinners or add value to it themselves.

With the exception of a limited number of producers of blankets, thewoolen system is almost nonexistent in the United States. China, India, Turkey, and, to a lesser extent, some Eastern European nations, now dominate carpet, rug, and heavier blanket production from the woolen system.

The worsted wool processing industry has shrunk significantly in the United States in the last twenty years because of wool demand. The majority of wool processing in the United States is primarily located in North and South Carolina. Other plants do exist in some eastern seaboard states.

The global shift in the textile industry is largely attributed to low wages in China, India, and other developing nations. But this shift is also due to rapid modernization of wool processing plants, particularly in China and India. The surviving textile mills in the United States have incorporated new technologies and can customize their products to specific consumer needs; socks for the US military for example.

Many of the steps in sheep’s wool processing require the use of chemicals and create byproducts that result in substantial costs in order to comply with environmental regulations. Environmental regulations are considerably less stringent in China, India, and other developing nations.

Other issues of concern to the U.S. wool processing industry include the removal of textile tariffs and quotas, and the claim that China has artificially kept its currency at a low value relative to the US dollar.

Another concern often mentioned is the decline in US sheep and wool production. However, demand for wool apparel goods has increased in the United States in the last ten years, and export of the US wool clip has increased from traditional levels of approximately 33% to 70% of the wool clip in fiscal year 2007. China now consumes more US raw wool than our domestic wool processing industry.

But it wasn’t always that way....

Some things I bet you never knew!

During the 16th and 17th centuries, England tried to discourage the wool industry in the American colonies. Nonetheless, colonists smuggled sheep into the States and developed a wool industry. By 1664 there were 10,000 sheep in the colonies. By 1698 America was exporting wool goods. England became outraged and outlawed wool trade. The restrictions on the raising of sheep as well as wool manufacturing were part of the outrages that led to the American Revolutionary War. Even after the war, England enacted laws forbidding the export of any sheep, however sheep’s wool was acceptable.

Following the introduction of Alpaca into the textile market by Sir Titus Salt in the early 1800s, Europe began a love affair with them. Alpaca was combined with mohair to create a softer, more pleasing woven fabric than had ever been available.

The want of finer textiles crossed the Atlantic Ocean and, in the 1850s, alpaca was being worn by America’s growing middle and upper classes. From bonnets and children’s clothing to suits and day frocks, generally in black, alpaca was a staple. While still being combined with mohair, these “suitings” were known as “alpaca” only, and commonly referred to:

- “Seated in the center, Mari Recque Lee wears the ultra-conservative “best black alpaca” of middle-aged women and with it a trim white linen collar and small white tie.”

- “(Bonnets 1863) I have another alpaca but it’s black – all the ladies have the black alpaca fever it being contagious and living in the same climate – I caught the fever. I have trimmed mine with a magenta edge...”

- “During the gold rush days of California, this young mother wears a neat, probably black, alpaca day dress, fitted over a corset and hoop, giving a smart, up-to-date effect.”

Uncle Sam gets involved

In 1865 two things happened that would change the face of the textile market here in the US forever.First, the American Sheep Industry Association was formed. Abraham Lincoln was President, the Civil War was ending, and neither the light bulb, automobile nor the telephone had been invented. This was the year the National Wool Growers’ Association came into being, making it the first national livestock association in the United States. With the assassination the President in April 1865, the administration was left clueless on the direction Lincoln had for our nation. Andrew Johnson was the first vice president to succeed to the presidency upon the assassination of a president. Historians commonly rank him as being among the worst US presidents because he had little regard for the will of the public. Andrew Johnson was the first US president to be impeached and his term expired in 1869.

To cover wartime expense, the United States put forth and approved the “Revision of the Revenue System of the United State 1865-1866”. In order to raise revenues the government looked at what was popular and what could be taxed: “...the silk tassels, the buttons, and the cover of silk, gingham, or alpaca, are all distinct products of manufacture; and each of these constituents, if of domestic production, pays a tax when sold of six per cent ad valorem or its equivalent.”

Additional items, such as canned goods and sugar were also taxed. These taxes, along with the economic problems in Europe and failing banks in the US, contributed greatly to the recession of 1873, which lasted until 1879. This time frame has been credited as the “roots that grew into the great depression”

Alpaca goods, originating in Great Britain, had been imported into the US through Canada. However, the new tariffs motivated a Canadian textile manufacturer’s move to Holyoke, MA. In 1873, employing three hundred workers, they began manufacturing alpaca goods under the name of Farr Alpaca Company. These goods, while still taxed, because of domestic production were taxed less.

In the later half of the 1800s American woolgrowers were looking anew at the future of sheep in the US.

“The attempt has been made in this country to manufacture alpaca goods from this long combing wool for which by reason of its luster is peculiarly fitted. ..Some failure occurred... they then sent to England and imported a thousand pounds of the best combing-wool and upon a comparison of that with the combing wool of Canada, it was found that the Canadian wool was equal to English in every respect (comparing long stranded alpaca with that of Marino wool) I have some specimens of this fabric which is called alpaca, because it is an imitation of the fabrics made from alpaca wool.”

“The mills in this country which have lately introduced the manufacture of alpaca fabrics from Canada combing-wools have at the same time produced the manufacture of Cobourge – a kind of soft stuff goods from the American merino fleece. ...It is working in England.. The price of English combing wool is now unprecedented. Australian merino combing wool, analogous to Vermont merino wools, advanced a fourpence a pound..”

The allure of the revenues that could be obtained from sheep’s wool set everyone in motion. Uses for the lanolin derived from sheep’s wool were expanded as well as lamb and mutton for meat. The complete package of the sheep was an easy sell. The National Wool Growers’ Association further pushed the government to increase tax liabilities on imports of wool and alpaca, to the tune of 85.5%, to promote the domestic production of sheep and a wool industry.

The Revenue Revision System was not embraced by American or Europeans. An outraged American population was now spending more money for their modest comforts. In 1890 the McKinley bill was enacted. It was devoted to the reform of the taxes collected on particular goods, because it asserted that the tariffs had created burdens that would be felt by the people. President Grant approved the McKinley Bill on the 1st of October 1890. The bill reduced the revenues from its high, and in many cases almost prohibitive duties; it put sugar on the free list, and it gave incentive pay to American sugar growers; it attempted to protect many "infant" industries such as the manufacture of tin-plate and sheep farmers who received, under its provision, reciprocal trade agreements.

Alpaca remained in favor until 1890 and then its popularity greatly diminished. While the Farr Alpaca Co remained in existence, fall-out from the depression caused it to close its doors in 1933. The company, while never changing its name, had been forced by the steep tariffs to step into wool production and abandon alpaca.

How does wool and alpaca shake out?

Now let’s compare alpaca wool and sheep’s wool.

Shorn from the sheep, wool is then scoured with detergents to remove the grease, dirt and other impurities. The detergents used must be harsher than that of cleaning agents for alpaca to ensure the grease is removed since alpaca has no grease. Often the grease is only moderately removed. This is the case in Aran knits, where the remaining grease adds a needed moisture barrier to the wool. Washing of Aran knits should never occur,so as to not wash the lanolin from the fibers.

Removal of the grease and contaminants causes shrinkage in theoverall volume processed. Shrinkage varies from one type of sheep’s wool to the next. While shrinkage does occur in alpaca it is not to the extent that occurs with wool, due to the lack of grease.

Wool, which is hollow and can absorb moisture, repels liquids. It is naturally hydrophilic. Hydrophilic means something that readily absorbs moisture, like a paper towel. Wool can absorb moisture almost one-third of its own weight. The remnants of the lanolin and the moisture retention are prime causes of the odor commonly associated with sheep’s wool. This odor can sometimes smell musty if the wool has not dried completely. Wool, however, is resistant to mold and mildew. People love that alpaca is odor free.

Part of the warmth factor in wool is that it absorbs moisture, in the hollow fibers, that the body naturally exudes. The heat from the body, along with the insulating air pockets that form naturally between the wool fibers, cause the moisture to vaporize in the core of each hair, building heat. This is why when wearing wool the wearer will be warm, and can often overheat.

Alpaca wicks moisture and never absorbs it. Alpaca is hydrophobic. The crimp in the alpaca wool fiber forces the strands to butt against each other, as opposed to lining up side by side or laying down flat together, just like sheep’s wool. This keeps the tiny air pockets intact, acting as little insulators - the key to being able to keep you both warm and cool. Air has the ability to move heat by convection. In other words, by moving and circulating. Through convection, air can transport heat from one place to another. When air is contained in very small pockets, it can't circulate easily, so heat is retained. Same goes for cold. Think about a Styrofoam cooler; the Styrofoam’s tiny pockets of air act as an insulator for heat or cold (depending on what's inside the cooler). The same concept goes for alpaca.

Bedouins in the Sahara Desert wear thin fabrics made of sheep’s wool to keep them cool in the searing heat. The secret to this is the tiny pockets of air within each wool fiber that provide both insulation and breathability. Think you can’t sell alpaca in warm climates – think again! Alpaca is a much better fiber when looking at breathability, not to mention wicking of body moisture. The moisture retention of sheep’s wool adds to its weight, although it is naturally a heavier fiber than most alpaca wool fibers. Alpaca is lighter and can be knit or woven into finer material than wool.

Wool is more durable than synthetics. However, repeated bending and pressure can break the sheep’s wool fibers. The arm patches seen on many traditional wool sweaters are there to protect the elbow so that the wool doesn’t break. If you have ever worn wool socks, you know the “hole” issue. Alpaca is far more durable than wool. It is stronger than wool and stretches a longer distance before reaching a breaking point. Sheep’s wool and alpaca share the characteristic of being wrinkle resistant and both retain their shape better than most fabrics.

Like alpaca wool, sheep’s wool leans towards being a green choice. Most modern facilities treat the animals humanely. The price commanded by wool encourages the consumer to take better care of the garment, extending its life and making it less likely to end up in a landfill.

As a protein-based fabric, again both sheep’s wool and alpaca wool are biodegradable. However some large wool facilities do use substantial amounts of energy, water, and chemicals to bring the fiber to the market. Weighed against the alternatives, wool remains an environmentally sound clothing choice. As more and more consumers express eco-friendly interest, wools that can be certified as organic, fair-trade, and carbon-neutral are beginning to appear on the market.

Sheep’s wool is naturally produced in many beautiful colors: black, gray, silver, brown, red, and moorit - a chocolate brown color - although white is the most prominent. Wool is easy to dye; the scales on the surface of the wool fiber diffuse light, giving less reflection and a softer color.The proteins in the core of the fiber absorb and combine with a wide variety of dyes and allow the wool to hold its color, as does alpaca wool. The difference is that alpaca dies vivid and has a beautiful natural luster.

Sheep’s wool does not have to be specially treated to become non- flammable. A fabric made entirely of wool is difficult to ignite, burns slowly, and has limited ability to sustain a flame. Wool does not melt when burned and so cannot stick to the skin and cause serious burns, unless blended with acrylic or polyester. This too is the case with alpaca wool.

While sheep’s wool fibers have a natural protective layer that prevents stains from being absorbed, they also pick up less dust, as they are static resistant. Alpaca, because of its hydrophobic nature, repels stains and also is not subject to static. Alpaca wool fiber’s composition lends it’s self to the collection of less dust and foreign odor – better than all other fibers. While recent innovations mean wool garments are no longer all ‘hand-wash only’, many wool garments can now be machine-washed and tumble dried. Sheep’s wool knits will shrink if washed and dried in a machine and can felt. This is the same for alpaca knits too, however the amount of felting is less.

The similarities thus far are many; however the one thing that sheep’s wool does have that alpaca does not are allergic reactions. Lanolin, as well as the dander which remain in sheep’s wool fiber’s scales, make wool a health hazard to anyone that is prone to wool allergies. Alpaca is naturally hypoallergenic making it safe for all to wear.

The number one complaint against wool is itch. This is because of the mechanics of the fiber itself, which irritates the skin. This appears to be especially true in people with skin conditions, such as eczema or atopic dermatitis.

It's likely that pain receptors are largely responsible for the prickle that's perceived from wearing wool and other fibers, including alpaca.

While often we tell people that alpaca doesn’t itch, it can. It isn’t the fiber - it’s the person. People vary in how they experience prickle and itch sensations from contact with natural and even synthetic fibers. In some particularly sensitive folks, their skin can redden from the exposure. The sensation can also depend on individual seasonal, physical and psychological factors, such as:

Qualities of the fibers themselves, such as length and thickness, may play parts in causing discomfort as well. For example, shorter fibers seem to heighten the perception of prickle, since there are more fiber ends to be felt in any given surface area of fabric. Similarly, coarser fibers appear more likely to intensify prickling sensation than fine fibers. Knits itch more than woven fabrics since the weave traps many of the fiber ends. Be that as it may, alpaca has a softer “hand” and a lighter feather touch on the skin, giving the wearer a morecomfortable experience.

Sheep’s wool is known for pilling. The finer the fiber the more fuzz balls that erupt on the surface of the knit or woven fabric. Alpaca pills less than wool in grades of baby alpaca, and superfine will rarely pill. Both fibers are prone to pilling in high friction areas - under the arms, on sleeves and inside the thigh area. However removal of pills from alpaca is easier because there are far fewer.

When asked, the International Alpaca Association stated, “Alpaca always improved wool.” I know that however, wool does not improve alpaca, although many claim it does. Rumors about durability and elasticity run rampant in regard to blending alpaca with wool. Yarns sold that are blends of wool and alpaca are done so primarily to reduce cost, yet sometimes a desired outlook is warranted by the marriage of these similar but different fibers.

So as a self-proclaimed purist when it comes to alpaca, have I ever blended wool with alpaca? Yes. I have done so with two specific products. First was a felted jacket done several years ago. I added wool to the alpaca so that it could be felted easier and more evenly. Once the fabric was made from the sheep and alpaca wools, the pieces were cut, assembled and sewn.

Next was a bulky knit vest, hat and scarf with mittens. The look I wanted was that of a pencil roving. It was unattainable in pure alpaca so we used a 52% alpaca, 18% wool, and 30% synthetic blend. The vest was a hit and sold very well. We have followed it upwith a men’s pullover that, along with the others, is still in the line today. It is my husband’s favorite sweater to wear when we travel to cold and blustery climates. We do have some new alpaca wool blended products for this year as well. Overall our alpaca wool blended products are less than 1% of our offering and done so to achieve a “look” or for a specific reason.

I have to say that, besides silk, wool is one of the few other fibers I will blend with. The similarities are so great, as are the differences, but the similarities are far more numerable. I think blending to create the desired look can be done effectively and lends itself to more cross- over of consumer awareness. The important part is to always disclose the fibers used and the amounts. This is so important for the consumer and is a must for ethical business.

So, in my estimation, alpaca wool and sheep’s wool might not be kissing cousins, but wool isn’t the black sheep of the family either.