Alpaca and the Miracle Fiber: Is it a Match?

Posted by Kim Brooks on 1st May 2014

A guilty pleasure of mine is watching ‘What Not to Wear’ and hoping that some day someone would nominate me, well sort of. If you are familiar with the show you will understand; if not check it out.

So, while wearing my ‘not so sexy’ sweats and lounging in front of the tube, I happily munched popcorn and watched as one of my “peers,” with an unhealthy retro vibe and addiction to all things synthetic, was transformed into a beauty right before my eyes. What caught me was Stacy and Clinton’s beef with her mainly acrylic, polyester and shiny wardrobe. From sweaters and blouses to pants and shoes, this gal had it all! They kept reiterating that she should wear “natural fibers”; look for clothing that is made from things that grow naturally in nature, and leave the plastic alone. Why?

Lets find out.

A bit of history:

In September 1931 American chemist Wallace Carothers reported on research carried out in the laboratories of the DuPont Company on "giant" molecules called polymers. Nylon, the "miracle fiber," was born.

Nylon's debut created a revolution in the fiber industry. Rayon and acetate had been derived from plant cellulose, but nylon was synthesized completely from petrochemicals. It established the basis for the ensuing discovery of an entirenew world of manufactured fibers. The Dupont Corporation created the firstcommercial acrylic fibers in 1941 and trademarked them under the name "Orlon" The creation of polyester and acrylic are actually pretty complicated chemicalprocesses, which can boggle the mind. To cut to the chase, these materials are a byproduct of the oil refining process that results in gasoline. Add this to a long list of products that are dependent on the ever more expensive crude oil.

DuPont began production of nylon in 1939. The first experimental testing used nylon as sewing thread in parachute fabric, and in women's hosiery. Nylon stockings were shown in February 1939 at the San Francisco Exposition - and the most exciting fashion innovation of the age was underway. The conversion of nylon production to civilian uses started and when the first small quantities of postwar nylon stockings were advertised, thousands of frenzied women lined up at New York department stores to buy them. An American Romance was born!

After the war, when GIs came home and families were reunited, economic growth surged. In the immediate post- war period, most nylon production was used to satisfy this enormous pent up demand for hosiery; but come the end of the 1940’s it was reaching other areas of the textile world and was being used in carpeting and automobile upholstery. Manufactured fibers continued their steady march and, by the 1950s, the industry was supplying more than 20%of the fibers needs by textile mills. A new fiber, "acrylic," was added to the list of names, as DuPont began production of this wool-like product.

You ask what happened to the popularity of natural fibers? The answer is Wash and Wear and Easy Care Acrylics! Couple that with the trends of the 60s and 70s, the modern vibe, and you have your answer. Today we find the marketplace saturated with man-made textiles. Can you believe that an estimated 8,000 chemicals are used to transform raw materials into clothes? It’s true, according to The Ecologist magazine.

To be called acrylic in the US, an item must contain at least 85% acrylonitrile (CH2CHCN). This is an important binder for the manufacture of plastics. In terms of its molecular structure, it consists of a vinyl group linked to a nitrile. While that may be far reaching for the needs of this article, did you know that the emissions of this chemical are the same as auto exhaust and cigarette smoke? Acrylonitrile is highly flammable and toxic. The burning material releases fumes of hydrogen cyanide and oxides of nitrogen. The International Agency for Research on Cancer (IARC) concluded that there is inadequate evidence in humans for the carcinogenicity of acrylonitrile, but classified it as a Class 2B carcinogen (possibly carcinogenic). The use of acrylic in women’s bras is being looked at. Could it be that this is a major contributor to breast cancer? Okay, so what doesn’t cause cancer these days?

So how is acrylic made? The fiber is produced by dissolving the polymer in a solvent such as N,N- dimethylformamide or sodium thiocyanate, forcing it through a multi- hole spinneret. The filaments bind together in a solution of the same solvent; this is known as wet spinning. Another method is to evaporate the remaining solvent in a stream of heated inert gas, also causing the filaments to bind together, this is known as dry spinning. Washing, stretching, drying and crimping complete the processing. Because acrylic is man made, the loft, thickness and softness can be regulated. Dyes can be applied to them and, once dyed, they are colorfast; they are odor and mildew resistant too. In cold weather acrylics provide light insulation and moderate warmth without the addition of extra weight.

Production of acrylic fibers is now centered in the far east, and production has been declining in Europe as production has ramped up in other areas. Where the US was once a leader in this industry, most, if not all plants are now shut down here. Former US brands of acrylic were Acrilan (Monsanto), Creslan (American Cyanamid), and Orlon (DuPont).

The key factor that lends acrylic fabric its quality of comfort is its ability of moisture transportation or wicking. Acrylic fiber has the ability to attract and convey moisture. Do to this quality, acrylic fiber offers great wicking capabilities to the super light fabrics that are made from it. These days active and sports wear are made from these acrylic fabrics, think Under Armour®, Lululemon Athletica and Nike®. Acrylic knitwear is durable, resistant to moths, and is very resistant to deterioration from sunlight exposure. However, static and pilling can be a problem. Moreover, acrylic has one significant problem: acrylic knitwear can stretch.

A heat-setting process stabilizes acrylic yarn and fabrics. When improperly stabilized, acrylic knitwear will stretch from the heat and tension in normal wear and with routine cleaning. Professional dry cleaners have had severe problems cleaning acrylic knitwear because of its tendency to grow and/or stretch. Once the fabric stretches, it cannot be re-blocked into shape. It is never advised to hang knitted sweaters on a hanger from the shoulders, wet or dry, since this will cause stretching and hanger marks that cannot be reversed.

Washing of 100% acrylic knitwear, is best done in a net bag on a gentle cycle with mild detergent or color-safe bleach. It is best to dry acrylic in a dryer on a warm cycle until 90 percent dry. This means that the areas of double thickness such as cuffs, collar and seams may feel damp. A hot dryer can cause areas to shrink or to melt. Pilling also is a problem with acrylic, and will occur over time as with other soft knitted fabrics. Drying acrylic without heat can also be an issue, as wrinkles from washing cannot be heated enough to release them from the fabric.

Stains such as coffee, tea, wine and soft drinks are relatively easy to remove from acrylic while stains such as vegetable oil; paint, nail polish and glue are very difficult to remove. The solutions needed for these types of stain removal will melt the acrylic fibers.

Use an iron sparingly and only for removing wrinkles. Synthetic fabrics do not hold up well under an iron; they will melt. Take this principal one step further and light polyester on fire, what do you get? Nothing other than a giant melted glob of plastic, which can be extremely painful on human flesh. This is why babies should never have synthetic blankets. Even those that have been treated to be fire resistant are covered in chemicals, which is a whole other article!

Blending acrylic with alpaca...?

When I started researching this specific blend I hit a wall...no data. So I contacted the International Alpaca Association. They specified that acrylic can give more bulk to the alpaca, if the yarn is engineered in that fashion. The only other benefit, they stated, if you can call it one, is a cheaper product. “Acrylic always cheapens alpaca.” Lilly said.

It seems we have our own urban myth regarding ‘the benefit of adding acrylic to alpaca for structure.’ Because of the inherent stretch properties of acrylics, they in no way shape or form, add structure to alpaca, Alpaca is far more sound and less likely to grow than acrylic.

When I contacted the alpaca production mills of Inca Tops they said, “Each fiber has its own characteristics and, when it is blended, by consequence the final blend will acquire characteristics of both components according to its ratio in the blend. The other component also modifies the price. Acrylic is cheap, resistant fiber. Blends are usually chosen by each customer to provide the desired characteristics to its garments and also to reach the desired level of price.”

China is increasingly offering alpaca acrylic blends. I was recently at the MAGIC show in Las Vegas. This is the largest apparel show in the world. I asked companies there if they used alpaca or alpaca blends. Angel from Revolution Now mentioned that he had investigated alpaca blends from China and that blends advertised as 20% alpaca were in actuality, after testing, only 3- 6%. It was his belief that the alpaca was being used to create a stronger demand and price for the yarn.

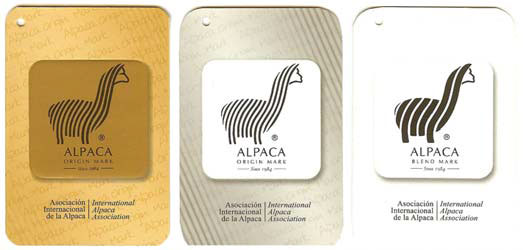

It is because of this factor that the International Alpaca Association created a quality control mechanism, Branded Hang Tags, to be used with alpaca. They have three levels of branding: Gold for 100% Baby Alpaca, Silver for 100% Superfine and White for blends.

The caveat is that blends must adhere to the percentages of alpaca specified, namely at least 30% alpaca, superfine or baby. This branding benefits the consumer, alerting them to the quantity and quality of alpaca, and ultimately a price that reflects both. As far as I know, in the US only two alpaca distributors carry, honor and offer this branding.

The major mills do offer yarn blends in 50% alpaca, 50% acrylic, often referred to as Alpacryl, as well as Boucle yarn which is a blend of 89% alpaca, 11% polyamide or polyester. This is one of those cases where, to get the desired effect of a nubby boucle yarn, the acrylic is added so that, during the spinning process, a portion of the fiber actually jumps away from the thread, creating the nubby boucle effect.

Alpaca acrylic sweaters can be identified by a sheen in the finished garment. This sheen is unlike that of natural alpaca and is caused by the final step of blocking the garment. Blocking is done with heat and steam. Alpaca acrylic knits once blocked, take on this sheen as the heat actually melts a tiny portion of the knit.

Are there benefits to blending with acrylic? Well in the case of socks, yes. Socks are among a growing market segment of high performance fabrics that acrylic benefits. Unlike cotton which holds moisture, acrylic wicks, probably better than any other fiber, and moves moisture away from the body. This wicking, combined with the natural wicking of alpaca, creates a sock that keeps feet dry and comfortable, while reducing the conditions that cause athletes foot, blisters, and other foot issues. Additionally, it enhances the performance of the wearer, creating a better grip by the foot because of the lack of moisture held next to the skin.

In looking at alpaca blends from the statement of the mills, “the final blend will acquire characteristics of both components according to its ratio in the blend.” We can determine that alpaca acrylic garments will be lightweight, cost less, and shorten the life of the sweater, due to various cleaning issues, and that they will pill. The garments will be thermal. However, we can safely assume they will be less thermal than 100% alpaca, the percentage less being dependent on the quantity of acrylic over alpaca the garments include. Forget natural; even natural colors would not qualify ifblended with acrylic.

So why do Stacy and Clinton want you to wear natural fibers? First and foremost, acrylic looks cheap. It doesn’t do our first impression any good. Natural fibers have a texture that looks rich and refined. The drape associated with natural fibers and the structure they impart are a great way to create a “Look”. We are judged by how we look, whether we like it or not.

The debate continue on whether or not synthetics are good for us. Acrylic can irritate the skin of people with dermatological conditions such as eczema. It is clear that natural fibers don’t impart the chemicals that acrylics do against our largest organ, the skin. Natural fibers are easier to care for, from an environmental standpoint, and can be cared for by hand washing using “soft” cleaners.

Their best advice: Look for clothing that reflects timeless style and quality. Look for brands that use fine fibers and quality workmanship so your purchase remains golden over time. This is the best use of your time and money. Stacy and Clinton will be proud.