Cotton Up To Cotton

Posted by Kim Brooks on 1st May 2014

Time to detail another fiber, and this one is a staple of our very existence.

Can you imagine getting out of the shower and drying off with a towel that isn’t cotton? Or sleeping in crisp polyester sheets, or pulling on your jeans made from hemp? No, its cotton. Cotton truly does make up the fabric of our very lives.

Everywhere I look there is cotton; from the drapes at my window, to the seat cushion I am sitting on. It is even in products I wouldn’t expect, like coffee filters, paper, feminine hygiene products, and the dollars in your pocket... yep, cotton plays a part.

As I sit here and write I am wearing at least 75% cotton. The other part of my wardrobe is my trusted alpaca socks and an alpaca cardigan. Yes, I wear alpaca every day, but I have to say, cotton is ever present.

So, in thinking about cotton we all have first hand experience. Personally, my family farms cotton here in California, along with tomatoes and other crops. My cousin sat on the Cotton Board a few years back and stays active in cotton legislation. Fresno, where I live, even has a cotton exchange. Who knew? It is a huge crop for California - huge for the US too.

But what makes cotton, cotton? And how did it change the landscape of our country?

Cotton is more than 7000 years old, yes that would be the 5th millennium BC, and was cultivated in western Pakistan.Cotton has also been found in the Mexico region dating back as far as 5800 BC.

The cotton plant, Gossypium, derived from the Arabic word goz, (if you are thinking “gauze” you are on track), refers to a “soft substance” and is a fruit bearing plant. It produces a flower and then the fruit, called a boil, which is really just a protective capsule for the seeds. Inside this capsule is the soft fluffy fiber with the seeds nestled within. When the boil dries it cracks open and the cotton fiber emerges.

There are four types of commercially grown cotton:

• Gossypium hirsutum – upland cotton, native to Central America, Mexico, the Caribbean and southern Florida, grown in North America (90% of world production) and our focus for this article.

• Gossypium hirsutum – upland cotton, native to Central America, Mexico, the Caribbean and southern Florida, grown in North America (90% of world production) and our focus for this article.

Cottonseed is a secondary product with many uses. It is used in three formats, oil, meal and hulls. The oil is used in cooking oil, salad dressing and shortening and it is also used in the making of snack foods, like crackers, cookies and chips. The meal and hulls are used as livestock, poultry and fish feed and also as fertilizer.

Cotton plants can be susceptible to blight, virus, fungus and boll weevils. Cotton uses more than twenty-five percent of all the insecticides in the world and twelve percent of all the pesticides. Cotton growers have, in the past, used as much as one quarter of all the pesticides used in the entire US. Now cotton is being genetically modified so as to reduce the need for the heavy reliance on pesticides.

No need for a history lesson, we all know that cotton has been in demand here in the US for years, and so much of our history revolves around it. From the cotton plantations of the south and the slaves that did the back breaking harvesting and cleaning to the industrial north wrapped up in manufacturing and shipping, cotton played a major role in the growth and development of our country.

The inception of the cotton gin, and the subsequent industrial revolution, fueled the need for cotton, and the US became a leader in the production of cotton clothing.

Many of the laws and regulations we have today came about from sweatshop labor in the north. One of the most famous incidents was the Triangle Shirtwaist Factory Fire on March 25, 1911.

Over 146 garment workers, most young immigrant women and girls, perished when the garment company they were employed by locked them inside. When fire broke out they were unable to exit the building. This led to the phrase, “Don’t mourn – Organize” and led ultimately to the formation of the Textile Workers Union. These and other events led to laws and protective measures, including government legislated insurance premiums for workers and management protection. This directly affects the textile production in the US today.

Believe it or not, the same thing happened in 2006 in the KTS Component and Textile Factory in Bangladesh. They are one of the main suppliers to Wal-Mart. I wonder if the death of over sixty-five people will spur legislative change in that country or perhaps the reduction of the twelve- hour work days at $4 per day?

The National Cotton Council is the main organization overseeing the cotton industry in the US. Initially formed in 1939, it is now one of the four components of Cotton Incorporated. It is involved in the legislative, regulatory and public policy issues as it relates to the cotton industry.

We are fortunate to have Nick Hahn, President and CEO of Alpaca United, working with it to promote alpaca. Nick is also the President and CEO of Cotton Incorporated, as well as managing partner and founder of Hahn International. Ltd. I contacted Nick for this article and left a message. Unfortunately he has not returned my call. I would have loved to ask him some questions directly about cotton and Cotton Inc.

The overall mission of Cotton Incorporated is “To increase the demand for and profitability of cotton through research and promotion.” with the most familiar arm being the “Seal of Cotton”, known though its various marketing efforts. Current spokespeople include celebrities, Kate Bosworth and Zooey Deschanel. If you haven’t seen the cotton Mystery Fiber website, you should! It’s a site to educate the uninformed fashion victims of other fibers and to promote cotton!

The Cotton Board serves the needs of US producers and importers, with the goal of increased demand and consumption of cotton. Additionally, there is the Cotton Council International, which develops foreign cotton markets.

How do they do it all?

Well they are funded by The National Cotton Council (voluntary dues from the seven cotton industry segments), The San Joaquin Valley Quality Cotton Growers Association, Supima, The American Cotton Shippers Association, Southern Cotton Growers Inc., American Cotton Marketing Cooperatives, Plains Cotton Growers Inc., The National Cottonseed Products Association, The United States Department of Agriculture and Ice Futures U.S.

Additionally, to fund the Cotton Board, all cotton harvested and ginned in the US, as well as imported, is assessed and fees are collected on every bale. This averages out to be about $2.10 per bale with each bale weighing 480lbs. As of March 2009 (most current figures located) the Cotton Council reported that the US production was 17.9 Million bales for the years 2006-2008.

Additionally, to fund the Cotton Board, all cotton harvested and ginned in the US, as well as imported, is assessed and fees are collected on every bale. This averages out to be about $2.10 per bale with each bale weighing 480lbs. As of March 2009 (most current figures located) the Cotton Council reported that the US production was 17.9 Million bales for the years 2006-2008.

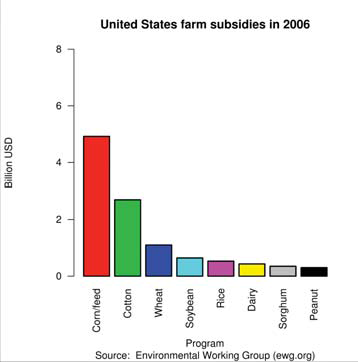

The Government plays a big role in cotton production as well. In order to keep the US competitive in the world marketplace we - you, me, the collective “we” - subsidize many things. Even Canadians pay via government levied taxes to subsidize fuel and other items. Cotton is no different. The US Government subsidies for cotton are at an all time low, $2.4 Billion dollars annually.The price of cotton was 48 cents/lb. in 1997 and bottomed out at 28 cents in 2000. Until 2003 the price continued to sell in the 48-cent range. At 48 cents a pound, cotton was being sold at about 30 cents less than the average cost to grow it and 40 cents less than the average of what US farmers received for it at the cotton gin. Subsidies? Sadly, only 36% of the 18,000 US farms receive the subsidies.

The US also pays Brazil $147 Million and it was announced on December 19, 2011 that, if approved by congress, we will soon be paying Benin, Burkina Faso, Chad and Mali, otherwise known as the C-4, $16 Million over four years. Why? To resolve cotton trade issues. Seems they are a bit upset that we are paying our farmers so much.

So, is there room for alpaca and cotton? You bet! Both serve a valuable purpose and both have benefits to the consumer that shouldn’t be ignored.

What about blending alpaca with cotton? A good idea?

To be clear, I do make and market a sock that is alpaca and cotton. Some folks love it, others, not so much. It was developed for sports and offers alpaca benefits, along with the absorption of cotton, while reducing the heat generating properties of 100% alpaca. I know others have done similar socks. These socks are not new to the industry. A few years ago when a company was talking about making blue jeans from alpaca, I just couldn’t wrap my head around it. The properties of the cotton, and the expectation of how jeans fit, feel and function wasn’t working for me. I also had a problem with blending a protein fiber with that of cellulose. Shrinkage on different levels was a concern based on the two distinctly different fibers. It works in socks because of the acrylic, but fabric? I took the stance, I would have to “see it to believe it.”

Isn’t karma funny when it bites you in the butt?

When I found an alpaca blend product in the marketplace, a Pima cotton knit jersey blended with alpaca, I couldn’t believe it. When I put it on, I was a believer. These two fibers were supposed to be together.

The fabric has the softness and feel of cotton with all the benefits of alpaca, wicking, warmth, breathability; but it is 100% machine washable and dryable without shrinkage and when wet, it dries faster than a 100% cotton equal.

Skeptical me, I had to find out, “What makes this work?”

Skeptical me, I had to find out, “What makes this work?”

The yarn, known as Alpacor® is a natural tec product that is built upon a micro fiber core, the finest in the world. The production process, as well as the product, is fully patented and developed in the US. It is quite remarkable. The Alpaca is wrapped around the micro poly core, so all that touches the skin is alpaca. It is soft, lustrous and silky. Because the alpaca that is being wound is such a fine thread, teeny tiny, it winds around the core tightly and smoothly, void of the wayward alpaca fibers seen in standard knitwear we all know and love. This contributes to the softness, the sheen and the hand, leaving the yarn and the garment, prickle free.

For this piece they use this Alpacor® yarn in conjunction with cotton yarn in a 50/50 blend.

So I got one. I wore it, and I really, really liked it. It is shown here in the image. Yes, I did get pink, I am a girl, after all.

Upon further investigation Stanfields in Canada is using Alpacor® in some of their designs and Christy Sports is working on distribution to the international outdoor market as well.

In talking with the folks at Alpacor® they told me that they are really excited about these products and I can see why.

In full disclosure, as this article goes to press my team and I are discussing how these natural tec fibers can be incorporated into more of what we offer to our customers. I am told that they take nature to the extreme. We have begun with socks, testing the water... one toe at a time. What's next? We'll see. So, will cotton be in one more thing?

Yes indeed.